Welcome to KON-FORM Kunststofftechnik GmbH

KON-FORM offers you the complete range of services from a single source:

Based on your customer requirements, we design and manufacture injection moulds and injection moulded parts from micro-series up to mass articles. On request, we will supply you with completely assembled components. In addition, we advise you on product design suitable for production as well as economic and energetic tool design.

Your specialist in mouldmaking and

injection moulding

Time is valuable …

… so we are happy to take it for you in order to understand your requirements and realise them to your complete satisfaction.

We advise you on both product design and mould layout. During mould design, we simulate the injection moulding process and carry out filling and warpage calculations for thermoplastics as well as fibre-filled plastics.

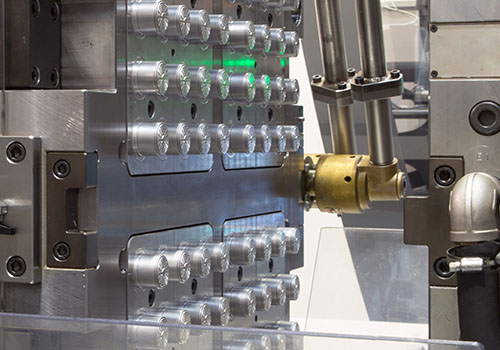

In our mould and tool making department we manufacture injection moulds up to 1.000 x 800 mm and up to 2,5 tons.

On our injection moulding machines with clamping forces from 250 to 2.600 KN, we produce complex technical 1K and 2K plastic parts for you in small to large series.

Talk to us about your project, be it a mould, a series production or a component production. In our company network with the Schock Metall Group, we will find the technically and economically tailored solution for you.

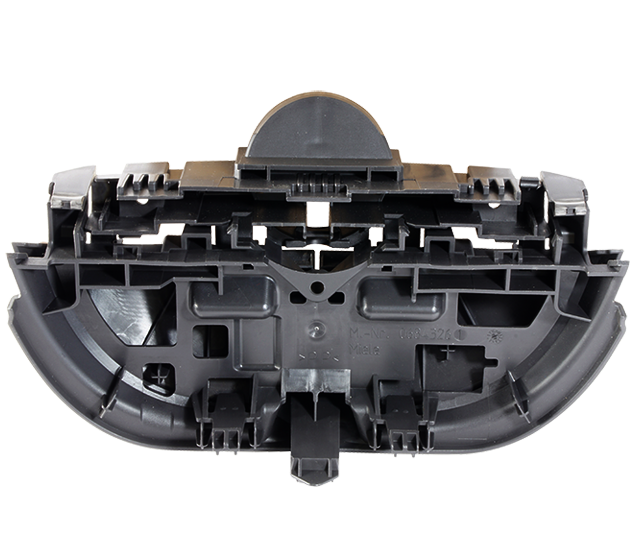

2K mould for an injection moulding machine

with core-back technology for the production of an exterior mirror housing with high-gloss polished outer contour and soft component on the interior side. The undercuts on the inside of the housing are demoulded with laser-sintered segments in the mould core to enable near-contour tempering.

Mould making

Precision in toolmaking is decisive for the quality of your products. Our experienced mould making team manufactures your tools professionally and functionally in sizes up to 1.000 x 800 mm and 2,5 tons…

Quality and environment

In 2001 the quality management system DIN EN ISO 9001 was introduced and in 2005 the environmental management system DIN EN ISO 14001 was implemented. Our way of working…

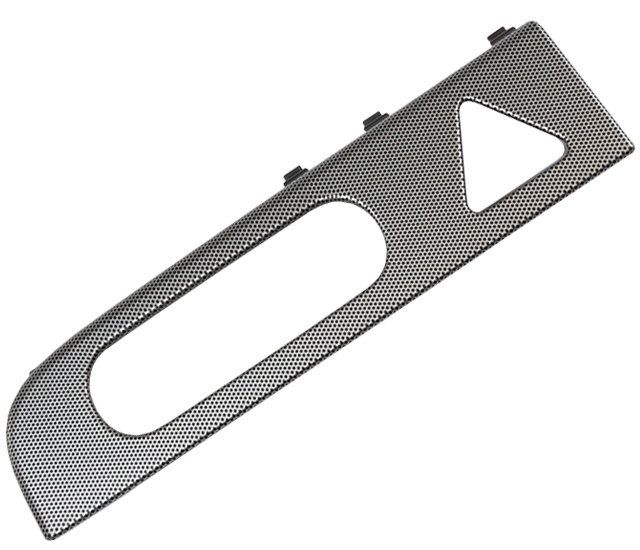

Injection moulding

Our machinery currently comprises injection moulding machines with clamping forces from 250 KN to 2600 KN for the production of complex technical 1K and 2K plastic parts…

SCHOCK GROUP – Precision in Motion

The SCHOCK GROUP is a European manufacturer of high-quality linear guides and telescopic slides for industrial applications. For many years, the group has stood for technical precision, a high level of vertical integration, and reliable standard as well as customized solutions.

The focus is on the development and production of telescopic slides, industrial slide systems, and heavy-duty systems used wherever loads must be moved safely, quietly, and reliably over the long term – from mechanical and plant engineering to vehicle and special-purpose vehicle construction, as well as storage, furniture, and automation solutions.

Development & Manufacturing in Europe

The SCHOCK GROUP combines development, design engineering, manufacturing, and final assembly within a strong European production network. Modern processes such as roll forming, CNC machining, precision ball cage technology, and powder coating ensure consistently high quality, dimensional accuracy, and long service life.

Within the SCHOCK GROUP, Kon-Form is responsible for development as well as the complete production of all injection-molded components. From design and toolmaking to sampling and series production, Kon-Form manufactures functional, durable plastic components that are precisely tailored to the mechanical requirements of the telescopic slides. This ensures optimal integration of plastic and metal components – delivering maximum functionality and consistently reproducible quality.

Thanks to the high level of vertical integration, both standard products and customer-specific solutions can be implemented flexibly and efficiently – including features such as soft-close, push-to-open, locking mechanisms, and customized surface finishes.

Quality you can rely on

SCHOCK telescopic slides stand for:

- Excellent running characteristics

- High functional reliability

- Long service life without maintenance

- Reliable supply chains within Europe

With a clear commitment to quality, short decision-making paths, and strong technical expertise, the SCHOCK GROUP supports its customers from the initial idea through to a solution ready for series production.

SCHOCK GROUP – Engineering in motion. Made in Europe.